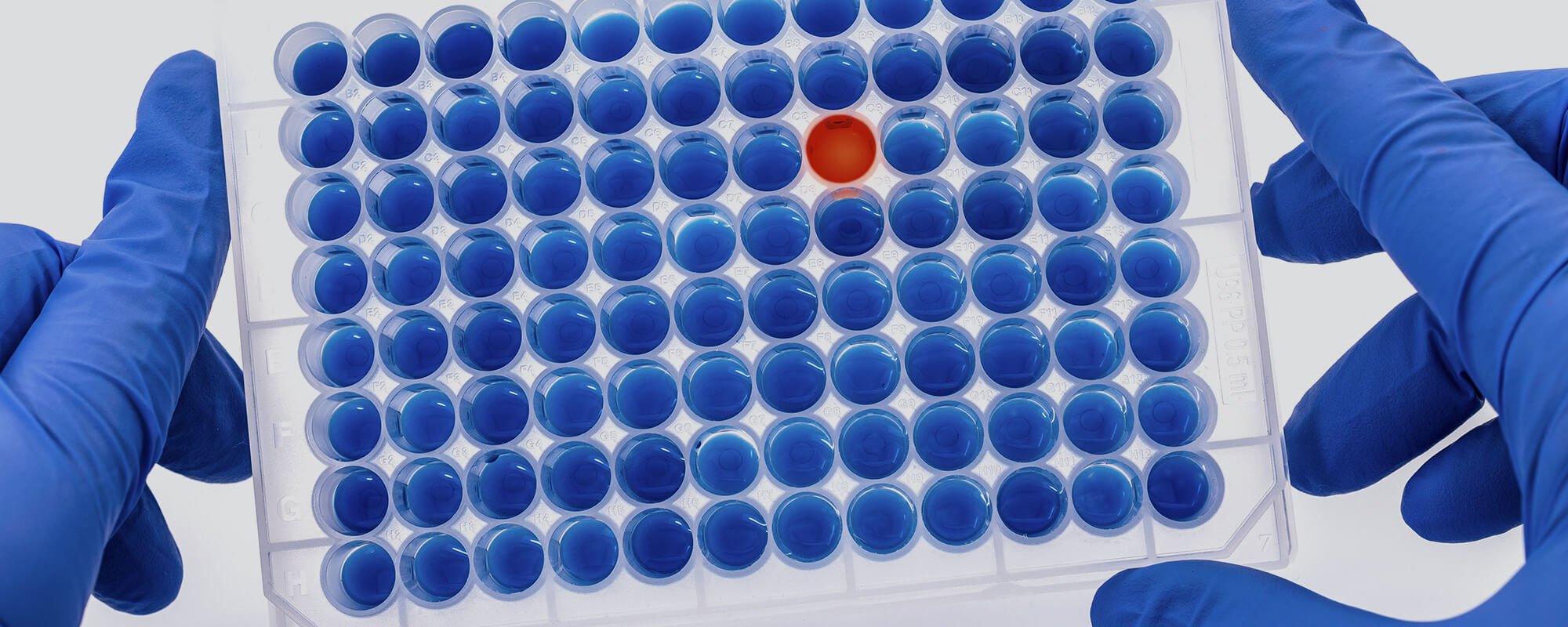

Are your sample volumes really what you think they are?

Find out for sure – with your:

process, liquids, and labware.

Real-Time Validation of Robotic Liquid Handlers

Knowing liquid volumes with a high degree of accuracy and precision is critical for high quality experimental data and for the correct interpretation of results: aliquot volumes directly determine reagent concentrations, one of the most important parameters in any experiment.

What if you could optimize liquid handling workflows and substantially improve quality control by tracking actual sample volumes through each step in your process? What if your liquid handler could use these actual volumes and compensate for variations in sample and transfer volumes? What if you could detect liquid handler errors in near real-time?

INTRODUCING THE

Meniscense VolumeSense™

Are you ready to revolutionize your workflow?

Fill out the form to request more info or to schedule a discovery call.